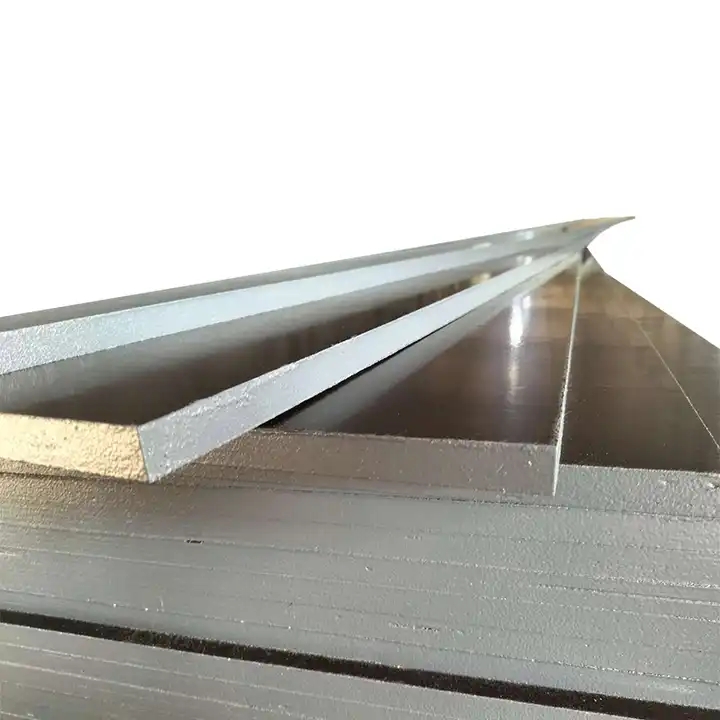

surface made from phenol or melamine on either or both sides which gives the plywood a higher resistance to moisture, abrasion,

chemical degradation and fungal attack compared to ordinary plywood.

Specifications:

Film | Black /Brown |

Grade | Excellent grade |

Press time | Three time pressed |

Core | Eucalyptus (Hardwood) |

Adhesive | Exterior Grade.Phenolic A Bond |

Thickness | 17 mm |

Specification | 600*1800x17mm/600*2400x17mm/1200*1800*17mm/1200*2400*17mm |

Logo | Customized |

Standard | AS6669:2016, AS/NZS2098.4:2006(R2016) |

Package | Standard export packing |

Price Term | 30% advance payment,the balance be paid against BL copy or irrevocable 100% LC at sight |

MOQ | 1x20GP |

Supply Capacity | 4500 cbm/month |

Usages | Can be widely used for construction concrete pouring, the face panel for any formwork system etc. |

Features | 1. Light weight, suitable for the high-rise buildings and bridge construction |

2. Corrosion Resistance: No pollution to concrete surface | |

3. Good weather resistance, can withstand temperatures -10℃~50℃ | |

4. The pouring surface is smooth, no need for secondary plastering, shortening the construction period and reducing labor cost. | |

5. Can be sawed, nailed, High-strength | |

Application | Civil construction, commercial construction, bridges, tunnels, dams, railways, and other construction projects |

We ZMADTO focus on construction plywood & wood formwork products to serve all construction Plywood &

wood products to serve all the construction requirement. Our production line include outdoor plywood which

is film faced plywood for construction and Indoor plywood include all types of commercial plywood, decorative

plywood and furniture plywood.

Our factory was established in 1993 and covers an area of 240,000 square meters with an average daily

output of more than 30,000 pcs plywood. Now we have more than 600 employees, including over 500 factory

workers and 35 professional technical managers, almost 100 sales and operation team. Besides, the factory

has more than 200 advanced equipment with the annual output of all wood products 600,000m³, After years

of continuous development, it has become a leading company in the international wood formwork industry

and exported to more than 20 countries around the world.

Exhibition Show

Packing & Delivery

FAQ

1. Q:Do you have factory ?

A:Yes, we also have own plywood factories to supply various plywoods and ensure fast delivery.

2. Q:What is your MOQ?

A:Normal MOQ is 1x20GP

3. Q:Could we get free samples?

A:Yes. Samples is freely prepared, but pls make freight collected by your side.

And This charge'll be deducted from total value once you order from us.

4. Q:How can you promise the quality?

A:To supply the high quality board to every customer. ZMADTO workers are serious in every process, every details,

from sourcing the timber/veneer to check panels piece by piece. Just to satisfy every customer, and make long term cooperation.

5, Q: What is your delivery time?

A: 15-25 working days after received advance payment or LC.

6, Q: What is the delivery port?

A: Qingdao, Tianjin.

7.Q:May I visit your factory for inspection before placing the order?

A: You are warmly welcome to visit our factory anytime. Please let us know your schedule in advance.

Related Products

Our advantages

1. More than 20 years of professional experience,

2. We will keep every promise firmly.

3. Superior quality wins us the trust from clients, quality first is always our tenet. We refine every details strictly.

4. Creation and innovation are critical for meeting the increasing demands of customers.

5. Good communication guarantees best understanding and lowest deviation.

6. Delivery on time will be ensured.

7. We will inspect every sheet before shipping out from our factory. The width, length, thickness, moisture, strength are all checked to make sure every sheet be qualified.

![UCIDA)~YF])L6G}[8K597WO.png UCIDA)~YF])L6G}[8K597WO.png](https://www.zmadto.com/upload/fortune/202309/25/202309251117516325.png)