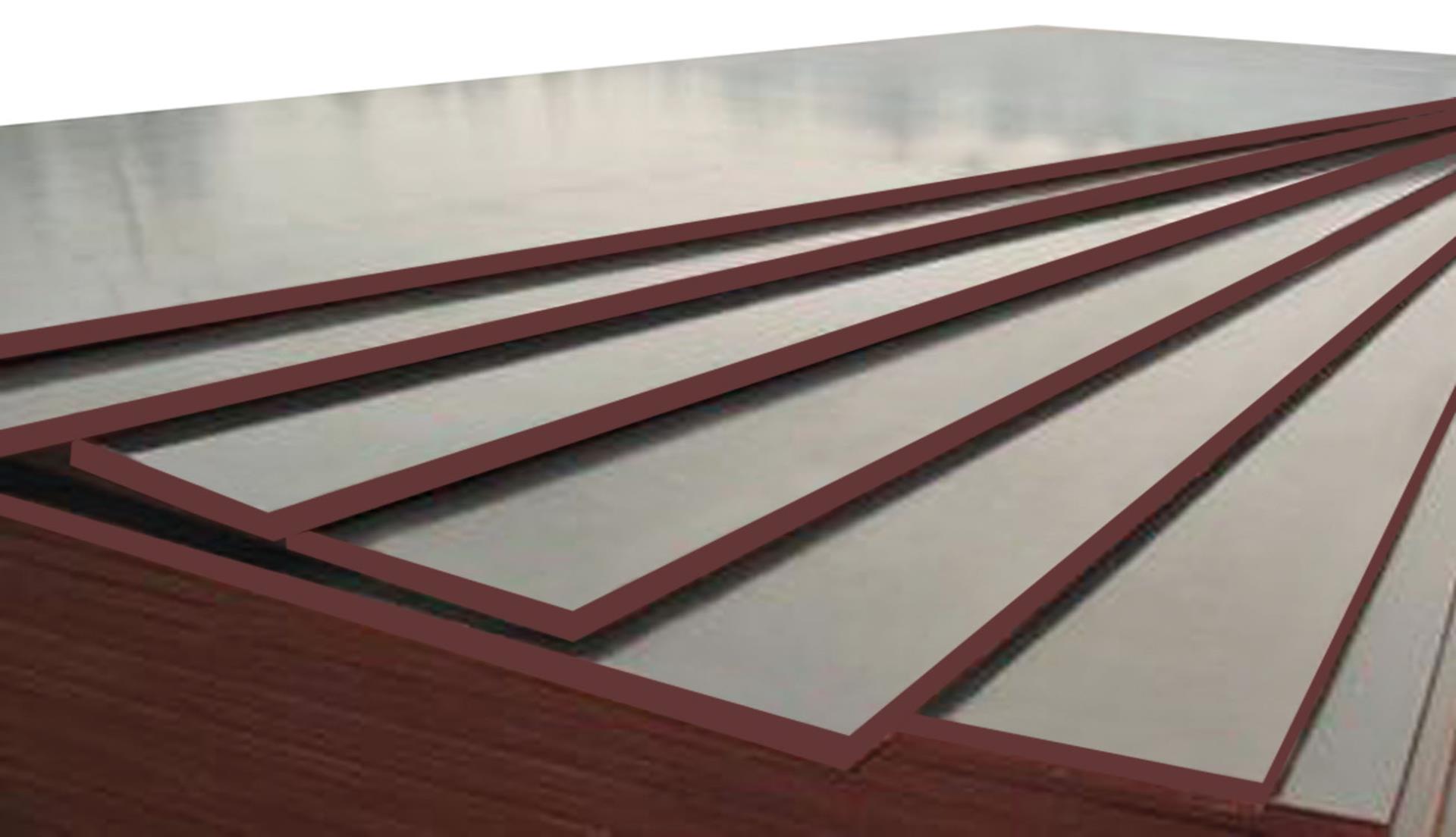

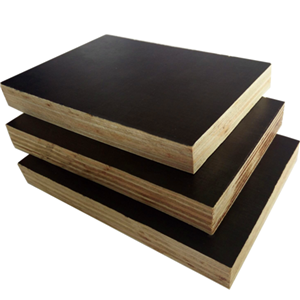

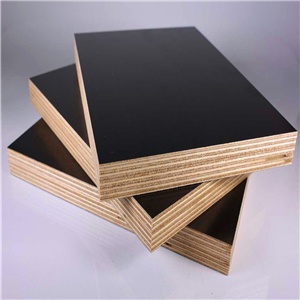

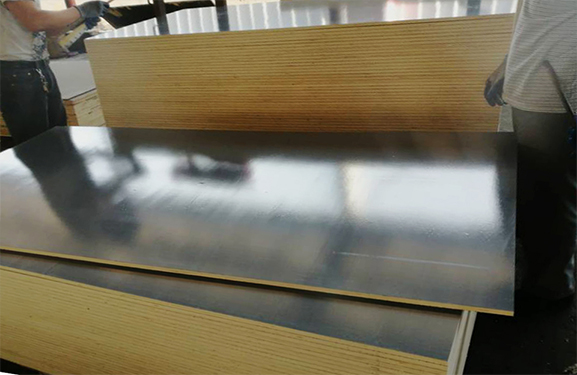

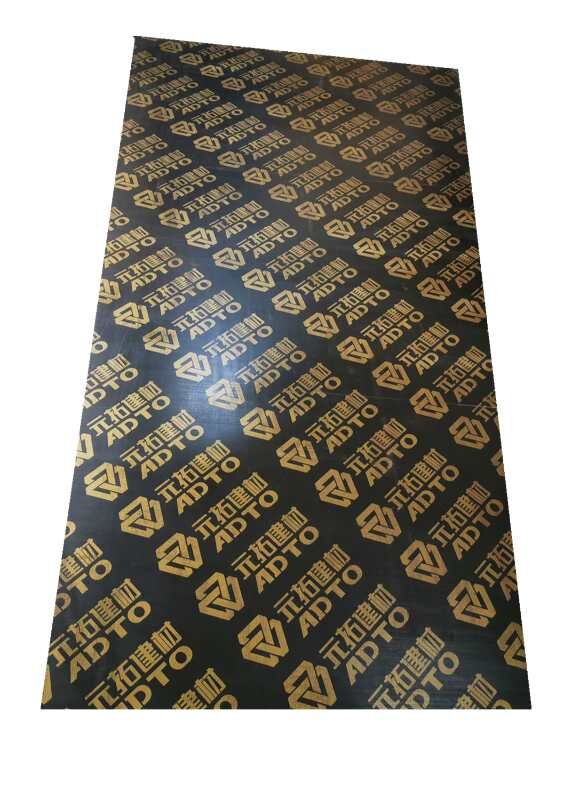

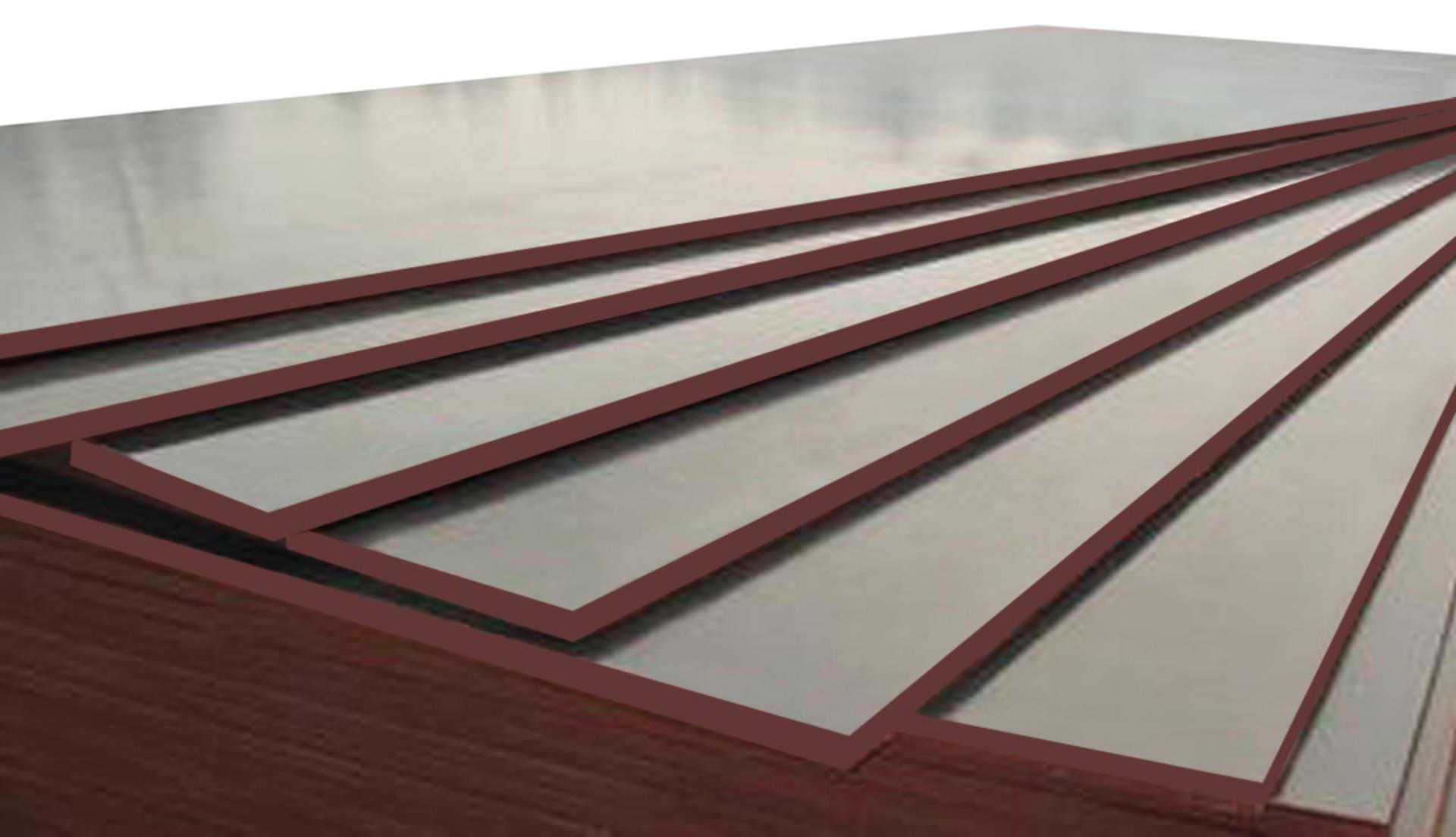

Film faced plywood is an exterior plywood used in building and construction projects. It has a special film coating on its surface made from phenol or melamine on either or both sides which gives the plywood a higher resistance to moisture, abrasion, chemical degradation and fungal attack compared to ordinary plywood.

Standard: GB/T17656-2008

Certificate: ISO, SGS, FSC,CE,INTERTEK,CNAS

Specifications:

| F/B | Black film/Brown film/Red film |

| Grade | Construntion grade |

| Press time | One time pressed/Two time pressed |

| Core | Poplar, hardwood, birch, pine, combi, etc. |

| Glue | MR, Melamine, Phenolic and WBP |

| Thickness | 9-25mm |

| Specification | 1220x2440mm, 1250x2500mm, 915x1830mm |

| Use time | 4-6 time, 6-8 times, 8-10times, 10-15 times |

| Moisture Content | 8-10% |

| Package | Standard export packing |

| Press Time | one times press/two time press |

| MOQ | 1x20GP |

| Supply Capacity | 4500 cbm/month |

| Usages | Can be widely used for construction concrete pouring, the face panel for any formwork system etc. |

| Formaldehyde Emission Standards | E2<30mg/100kg |

| E1<9mg/100kg | |

| E0<5mg/100kg Phenolic film faced plywood | |

| Features | 1. Light weight, suitable for the high-rise buildings and bridge construction |

| 2. Corrosion Resistance: No pollution to concrete surface | |

| 3. Good weather resistance, can withstand temperatures -10℃~50℃ | |

| 4. The pouring surface is smooth, no need for secondary plastering, shortening the construction period and reducing labor cost. | |

| 5. Can be sawed, nailed, High-strength | |

| Application | Civil construction, commercial construction, bridges, tunnels, dams, railways, and other construction projects |